- Products

- For Industrial

- For High Purity

- For Lab & Research

- BTU Wobbe CARI Calorimeters

- CEMS Analyzers

- Cavity Ring-Down Spectroscopy Analyzers

- Dew Point Chilled Mirror Analyzers

- Dew Point Moisture Meters

- Excimer Total Sulfur-Nitrogen Lab & Process Analyzers

- 开云app官方网站登录

- Optical Absorption Spectroscopy Analyzers

- Oxygen Analyzers & Safety Monitors

- Relative Humidity Analyzers

- kaiyun开云平台体育官方网站

- kaiyun开云平台

- Applications

- Application Assistance

- Agricultural Production

- Airborne Molecular Contaminants

- Air Separation Units & Nitrogen Plants

- Atmospheric & Air Quality

- Battery Manufacturing

- Benzene Fenceline Monitoring

- Biofuel Analysis

- Carbon Capture

- Chemical Manufacturing

- Energy

- Environmental Monitoring

- Evolved Gas Analysis

- Flare Gas

- Food and Beverage

- Gas Purity Analysis

- Hydrogen Production

- Lab & Research

- Petrochemical and Refining

- Pharmaceuticals, Life Science & Biotechnology

- Semiconductor

- Steelmaking Basic Oxygen Process

- Water Quality Analysis (TOC COD BOD TNb)

- Resources

- Service

- Application Assistance

- Commissioning

- Data Services

- Service Contracts

- Spares & Upgrades

- Training

- RMA for Oxygen Monitors

- Rental CRDS Analyzers

- Remote Connected Service

- Analyzer Performance Verification Program

- Commercial Humidity Calibration Laboratories

- Accredited SCS Calibration Laboratory

- Accredited DAkkS Calibration Laboratory

- About Us

- Events

- Careers

- Contact

MAX300-BIO

- Home

- Products

- Industrial

- 开云app官方网站登录

- MAX300-BIO

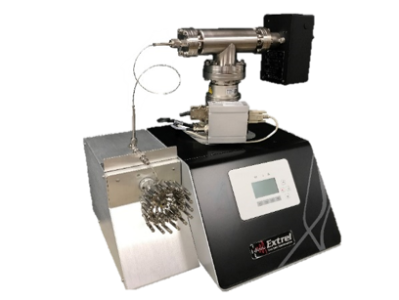

Unmatched Technology for Bioreactor Monitoring Applications

Powerful Mass Spec Technology

Mass Spectrometry is a powerful tool for bioreactormonitoring. Changes to the composition of bioreactor or fermenter off-gas provide crucial insight into cellular health and production efficiency. This makes the fast, accurate analysis of CO2, O2, N2, Ar, H2O and other compounds essential for real-time process control. OurEXTREL™MAX300-BIO™bioreactor monitor gas analyzeruses cutting edge quadrupole mass spectrometer technology to quantify bioreactor gases from multiple reactors within the facility and reports the data to the control system in real-time. One MAX300-BIO bioreactor monitor gas analyzer is capable of analyzing up to 80 samples with the use of a single FAST multi-port valve.Accurate off-gas analysis tells the control loop exactly what is happening inside each reactor without the risks involved with probes or manual sampling.

The MAX300-BIO bioreactor monitor gas analyzer is a powerful analytical instrument designed for monitoring the gases produced and consumed during biological fermentation processes. Here are some of the benefits:

- Accurate and Reliable:Provides accurate and reliable measurements of gas concentrations, ensuring the optimization of bioreactor performance.

- 实时监控:Provides real-time monitoring of gas concentrations, allowing for quick adjustments to bioreactor conditions.

- Easy to Use:Easy to use, with an intuitive interface and simple calibration procedure.

- Low Maintenance:Requires minimal maintenance, reducing downtime and maintenance costs.

- Multiple Gas Detection:Capable of detecting multiple gases simultaneously, including CO2, O2, H2, and CH4, making it a versatile option for bioreactor monitoring.

- Comprehensive Data Analysis:Includes data analysis software, allowing for comprehensive data analysis and visualization.

- Enhanced Bioreactor Performance:使生物反应器性能的优化, leading to increased yields and improved product quality.

benefits

- Quantitative analysis of individual contaminants PPT detection limits

- 分析时间间隔,以秒为单位

- Measures CO2, O2, N2, H2O, alcohols, contaminants, and more

- Samples without risk of contamination

- Calculates control parameters in real-time (e.g. Respiratory Quotient)

- Provides flow and mass balance data

- Multiport sample systems for up to 80+ reactors

- High precision and accuracy for optimal process automation

- Low maintenance, utilities and calibration required

- Complete method scale-up

- Lab, Pilot, Production

calculates the key indicators of organism health and process efficiency

- Carbon Dioxide Evolution Rate (CER)

- Oxygen Uptake Rate (OUR)

- Respiratory Quotient (RQ)

- Total Gas Flow

- Total Mass Balance

- Liquid Concentrations in the vessel

- Batch Quality – Analysis of minor ppm/ppb level components such as formaldehyde, methanol, acetic acid, etc.

- Gases Measured: CO2, O2, N2, HVO, argon, ethanol, methanol, formaldehyde, AND others

The MAX300-BIO Bioreactor Gas AnalyzerandMAX300-RTG 2.0 Industrial Gas Analyzerhave been installed in major manufacturing stages within pharmaceutical industries. One of the main applications isfermentation process control. In the fermentation process, the growth of bacteria and production of drugs takes place under very tight conditions. The aeration rate, temperature and dosage of nutrients are regulated very closely during several stages of the process. The Quadrupole Mass Spectrometer is used to provide full, fast and precise analysis of the incoming air and the off gas from the Fermenter.

The results are used to calculate the Respiratory Quotient (RQ), a major parameter in controlling growth and health of the bacteria. In different stages of a batchfermentation process, the RQ value changes, thus allowing for optimum and efficient drug production. The additional analysis of minor concentrations of by-products allows for rapid process adjustment to avoid undesired reactions. This multi-stream capability makes the MAX300-BIO the economical alternative to infrared and oxygen analyzers installed on top of each Fermenter.

The MAX300-BIO bioreactor monitor gas analyzer is designed for use in the biopharmaceutical industry, specifically for monitoring the gas composition in bioreactor vessels during the production of biologics and other biological products. Some of the industries that use the MAX300-BIO™ bioreactor monitor gas analyzer include:

- Biopharmaceutical Industry:Used in the biopharmaceutical industry for monitoring the gas composition in bioreactor vessels during the production of vaccines, monoclonal antibodies, and other biologics.

- Academic and Research Institutions:Used in academic and research institutions for studying the metabolism of cells in bioreactor vessels and for developing new bioprocessing methods.

- Contract Manufacturing Organizations:Used in contract manufacturing organizations (CMOs) that produce biologics on behalf of biopharmaceutical companies.

- Food and Beverage Industry:Used in the food and beverage industry for monitoring the gas composition in fermentation vessels during the production of beer, wine, and other fermented products.

Mass Spectrometer for Bioreactor &

Fermentation Applications

Need help? Complete our Mass Spectrometer

Application Questionnaire.

Applications

• Biofuels

• Ethanol

•Pharmaceutical

• Enzymes

• Antibiotics

• Steroids

• Vitamins

• Biomass

• Biopolymers

• Alcoholic Beverages

• Bread Products

• Waste Treatment

GET A QUOTE TODAY | SALES | SERVICE | TRAINING

Americas +1 412.967.5754

EMEA +49 69 20436910

China/APAC +86 400 086 0106

Our Mass Spectrometers for Industrial Applications

our solutions flyers

Questions? We’re here to help.

Terms and Conditions of Sale - Extrel

Sellers-Agreement-Purchasing-Terms-PUR-0026-FR-rev3 - Extrel

Terms and Conditions – Process Insights Swiss AG - MBW

Terms and Conditions – Tiger Optics

Terms and Conditions – Process Insights AG - LAR

Terms and Conditions – Guided Wave

Terms and Conditions of Sale – COSA Xentaur

SITE MAP

Copyright © 2023 Process Insights, Inc. All Rights Reserved.